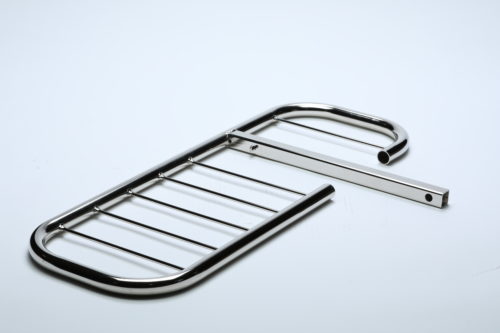

Metal tubing plays a vital role in products and industries across the globe. From mobile and portable displays to decorative ironwork and electrical conduits, the strength, weight, cost-effectiveness, and versatility of metal tubing makes it suitable for both turnkey OEM products and prototyping next-level product solution. Metal tubing is also highly formable and compatible with a wide variety of materials to provide the strength, tolerance, aesthetics, and unique qualities needed for a specific project.

Types of Tube Forming

There is a wide variety of metal tube fabrication techniques, tools, and processes to meet specific product requirements. Each of these tube forming methods offers unique advantages and works for specific material types. Tube forming can be broken down into two primary categories:

- Form-bound tube bending: In this type of tube forming, the form of the tube is made to the shape of a die. Some examples of this include rotary bending and press bending.

- Freeform tube bending: In this type of tube forming, the form of the tube is made by manipulating metal as it moves throughout the tooling. Roll bending is a great example of this type of bending.

There are also two categories of bending relating to temperature:

- Cold tube bending: Press bending, compression bending, and rotary draw bending are examples of cold tube bending. The metal tube is bent at room temperature, and force is used to shape the end product — not heat.

- Hot tube bending: Heat induction bending and hot-slab bending are examples of hot tube bending. The metal is bent using heat as the primary manipulative force.

Other tube forming processes include:

- Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media.

- Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting.

- Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part.

- Swaging: Swaging uses a die to manipulate the size of the tube diameter using force.

- Flatten & trim: Often used for tubular assemblies, flattening flattens the end of the tube. Trimming trims off the ends of the tube corners — often for fastening purposes.

- Mandrel forming: Mandrels can be inserted into the tube during the forming process to prevent deformation and defects.

There is a wide variety of metal tube fabrication techniques, tools, and processes to meet specific product requirements. Each of these tube forming methods offers unique advantages and works for specific material types. Tube forming can be broken down into two primary categories:

- Form-bound tube bending: In this type of tube forming, the form of the tube is made to the shape of a die. Some examples of this include rotary bending and press bending.

- Freeform tube bending: In this type of tube forming, the form of the tube is made by manipulating metal as it moves throughout the tooling. Roll bending is a great example of this type of bending.

There are also two categories of bending relating to temperature:

- Cold tube bending: Press bending, compression bending, and rotary draw bending are examples of cold tube bending. The metal tube is bent at room temperature, and force is used to shape the end product — not heat.

- Hot tube bending: Heat induction bending and hot-slab bending are examples of hot tube bending. The metal is bent using heat as the primary manipulative force.

Other tube forming processes include:

- Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media.

- Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting.

- Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part.

- Swaging: Swaging uses a die to manipulate the size of the tube diameter using force.

- Flatten & trim: Often used for tubular assemblies, flattening flattens the end of the tube. Trimming trims off the ends of the tube corners — often for fastening purposes.

- Mandrel forming: Mandrels can be inserted into the tube during the forming process to prevent deformation and defects.

Tubing Materials

Metal tubing provides several advantages over plastic tubing. It’s more durable, strong, and aesthetic. The primary draw of metal tubing is that it lasts significantly longer than plastic, and it can be viewed as a lifelong component — not a temporary one. There are several types of tubing materials that can be leveraged during the metal tube forming process. These include:

- Metal: There are a variety of metal grades used in tubing, including both ferrous (i.e., iron and steel-containing) and non-ferrous (i.e., non-iron) materials.

- Aluminum: This incredibly lightweight and corrosion-resistant material is used across industries and for many applications (such as construction, plumbing, or furniture.) Often, aluminum is alloyed with other materials (e.g., silicon, copper, manganese, etc.) to boost its hardness.

- Steel: Both steel and stainless steel are regularly used in metal tubing. Steel is strong and heat-resistant, while stainless steel provides chemical and corrosion resistance. Both types of steel can be alloyed with other materials.

- Copper: With high corrosion resistance and conductivity, copper is used in industries like power for wiring. However, it’s also aesthetically pleasing, making it ideal for certain furniture or construction applications.

- Brass: This is another metal with good strength, conductivity, and corrosion resistance.

At Northern Metal Products, we will work closely with you to determine the best metals or metal alloys for your specific application.

Industries Served

Metal tubing is used in many industries, including:

- Electrical conduits: Metal tubing makes a fantastic electrical conduit for wires.

- Aerospace: Metal tubing is used throughout plane components, such as in heat exchangers. The aerospace industry also utilizes metal tubing for chemical and pollution control.

- Automotive: You can find metal tubing in many vehicle components, including frames, seat adjustments, headrests, transmissions, instrument panels, and steering wheels.

- Landscaping equipment and tractor components: Like commercial vehicles, landscaping equipment and tractors utilize metal tubing in engines and throughout the frame and body of the equipment.

- Agriculture: Metal tubing is used during the manufacturing of many food products, such as in non-corrosive dairy tubing.

- Electrical: The electrical industry uses metal tubing for both conductive and non-conductive reasons.

Exercise equipment: A variety of exercise equipment leverages metal tubing for mechanical and framing requirements.

Metal Tubing & Fabrication From Northern Metal Products

Metal tubing is highly formable and used across many industries to create products we all use every day. With a variety of materials, processes, tools, and techniques, metal tubing can be formulated to meet your unique requirements. Northern Metal Products is an industry leader in metal tubing, and we have the experience, capabilities, and state-of-the-art equipment you need for your next prototype or turnkey product run.

To learn more about our metal tubing capabilities, contact us or get a quote today!