What metals can be used for metal fabrication?

Metals used for fabrication are generally selected based on their high strength, conductivity, flexibility, and corrosion-resistant properties. Some of the most common metals used in metal fabrication include:

● Carbon steel. Often used for the fabrication of industrial components, carbon steel is highly versatile and easily machinable. This heavy-duty material offers exceptional strength and durability while also allowing for clean, high-quality finishes.

● Aluminum. Aluminum is lightweight, conductive, and corrosion-resistant. With a high strength-to-weight ratio, this material is softer and easier to work with than some other metals. Aluminum is also non-toxic, reflective, and receptive to most standard fabrication techniques.

● Stainless steel. Composed of carbon steel, aluminum, and chromium, stainless steel alloys are highly resistant to corrosion, strong, and offer a unique, polished finish. This material can be fabricated in several ways, though the most common are work hardening (deformation), machining, and welding.

● Other materials. Plate and sheet metals, fittings, tubing, and wires/rods can also be fabricated in a variety of ways to produce parts or components with desired attributes for applications across diverse industries. Learn more about our material capabilities here!

What are the different fabrication processes?

Northern Metal Products offers a variety of metal fabrication processes, including:

- Wire forming. Wire forming is a process used to bend metal wires/rods into customized shapes.

- Welding. Welding involves joining two or more pieces using a combination of heat and pressure.

- Laser cutting. Laser cutting uses a laser beam to cut metal into desired pieces.

- Bending and forming. Bending and forming is the process of using force to manipulate metal into a desired shape while still in a solid state.

- Tube fabrication. Tube fabrication involves bending, cutting, or shaping of metal tubing.

- Powder coating/finishing. This process is used to apply dry, free-flowing powder to a fabricated piece to harden it.

- Machining. Machining is used to shape metal by removing unwanted material through drilling, turning, or milling.

- Stamping. In stamping, a turret is used to punch an indentation into the metal to create a shape, letter, or image.

What parts can be fabricated?

With a spectrum of materials and methods available, metal fabrication can be used to create numerous parts for prototype or large-scale runs. We offer metal fabrication services to a variety of industries, including:

- Aerospace, military/defense. Aerospace and military/defense industries use metal fabrication to create parts for propulsion systems and satellites.

- Agricultural. The agricultural industry utilized metal fabrication to create frames and support structures.

- Alternative energy. Metal fabrication is used to create solar, wind, and geothermal components like brackets, electrical enclosures, and frames.

- Automotive. Valve caps, pumps, covers, and other engine parts can be created using metal fabrication.

- Construction. The construction industry uses metal fabrication to create H-, I-, and T-beams, tubes, and pipes.

- Consumer products. Consumer products such as household appliances and furniture are constructed using metal fabricated parts.

- Original equipment manufacturers. The OEM industry can use metal fabrication to create custom products of any variety.

- Recreational vehicles. Metal fabricated parts are used for motorcycles, boats, etc.

As a contract manufacturer, Northern Metal Products is able to create a wide range of metal and wood products, including:

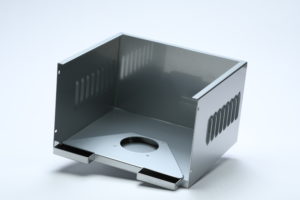

- Computer chassis

- Chair legs/frames

- Wire baskets

- Fridge/freezer shelving

Northern Metal Products’ OEM Metal Fabrication

Northern Metal Products is an ISO 9001-2015 certified, full-service manufacturing facility that offers turnkey, custom solutions for manufacturing needs as well as POP retail display fabrication for a diverse variety of industries. We offer many metal fabrication services, including laser cutting, bending and forming, tube fabrication, wire fabrication and assembly, and wood fabrication. To learn more about our OEM fabrication capabilities, contact us, or request a quote today.